Customer Services

Copyright © 2025 Desertcart Holdings Limited

🎨 Mold your masterpiece faster with flawless precision!

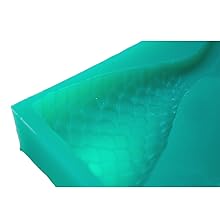

The BBDINO Silicone Mold Making Kit offers 21.5 oz of platinum-grade, food-safe liquid silicone rubber with a unique jade green tint for easy mixing verification. It cures rapidly at room temperature in 30 minutes, delivering flexible, durable molds perfect for 3D and flat designs. Designed for versatility across resin, wax, soap, and candle casting, this kit boasts a long shelf life and user-friendly packaging, making it a top choice for both hobbyists and professionals.

| ASIN | B09BFGQ37Q |

| Amazon Bestseller | #793,273 in Hobbies ( See Top 100 in Hobbies ) #6,997 in Jewelry Resin Casting Molds |

| Item model number | SI200 |

| Manufacturer | SIPOLYSUN TECHNOLOGY |

| Product Dimensions | 14 x 13 x 6 cm; 600 g |

R**A

De muy buena calidad, fácil de usar.

H**N

I did make a few moulds but quite expensive.

O**A

I highly recommend it, very good

J**H

Vorteil: Das Silikon entlüftet sich sehr zuverlässig selbst und ist extrem dünnflüssig. Dadurch läuft es in wirklich jede noch so kleine Vertiefung und bildet feine Details sauber ab. Nachteil: Genau wegen dieser Flüssigkeit kann es auch leicht aus winzigen Spalten herauslaufen, weshalb eine absolut dichte Form nötig ist. Die Aushärtung dauert außerdem länger. Man muss wissen, worauf man sich einlässt, bekommt dafür aber eine sehr hohe Abbildungsqualität.

S**E

I do a lot of 3D printing, but I needed to make a part that was both flexible and durable that I couldn't 3D print. Partly because of the shape, and partly because my printer can't handle super-flexible filament. I saw this stuff on Amazon and it seemed like it might work, so I ordered the small kit. I then 3D printed a mold in PLA, then coated the parts that needed to be smooth in XTC-3D epoxy. For the parts where surface didn't matter, I just left the raw PLA, layer lines and all. Because of the odd shape, I had to make a 4-part mold that could be screwed together. Once the epoxy was dry, I mixed up a batch of this BBDINO silicone, being careful to be as precise as possible with measuring. After mixing thoroughly, I took a 60ml syringe and sucked up all the silicone mix and then squirted it through the access hole in the top of my mold until it started coming out of the vent holes. At first it went pretty well, but after a couple minutes the silicone started seeping through the joints of the mold. I figured that might happen since this stuff is pretty thin - which is a good thing for getting it to flow into all nooks and crannies of the mold, but I should have done a better job sealing it. I made a frantic effort to tape up the seams to try and stop the leaks. Fortunately, it worked for the most part. But because a little bit leaked out, I didn't have quite enough to fill to the top anymore, so I quickly mixed up a second small batch and injected that as well. No big deal. I left the syringe sitting in the filler with a little excess in it so it would top off the mold if any more leaked out as it cured. Unfortunately, I got a little impatient and pulled the syringe out about an hour later, before it was completely cured and the "plug" for the hole pulled out with it because it was still soft. It didn't hurt anything in the end, other than to leave a slight dip in the finished surface instead of a plug that could be cut flush. Lesson learned. I couldn't wait to see how it came out. The instructions say to wait 5 hours before demolding, but I did it after a little more than 4. It was perfect! (other than the dip mentioned above). In order to completely remove it from the mold I had to stretch it around parts to get it loose. It's quite durable! I had to stretch quite a bit and it showed no signs of tearing. There was a lot of flashing from where it had leaked into the joints of the mold, but that was easy enough to trim off. They even supply a tool for doing so, though I didn't try it. It picked up every detail of the mold, including of course the layer lines. I had no trouble with it sticking to anything. Even the rough layer lines of the PLA. It came out of the syringe and mixing cups easily too, just by pulling on it. I have to say I am thrilled with how things turned out. I will definitely be using this stuff again if I need to make more squishy parts. Follow up almost 2 years later: Still happy with the quality of the results. While I did finally tear one of them, it had taken quite a bit of abuse before that point. When I poured the first molds, I had quite a bit of leftover mix, so I stuck it on the shelf and forgot about it until the other day. I expected that after having been opened for all this time, it probably wouldn't work very well anymore. Much to my surprise, the new pours came out just as good as the first ones. I didn't expect such a long shelf life, but I'm happy to be surprised.

Trustpilot

1 week ago

3 weeks ago